Specialist Tahoe Instrument Cluster Repair Services: Your Option for Faulty Gauges

Specialist Tahoe Instrument Cluster Repair Services: Your Option for Faulty Gauges

Blog Article

Ultimate Resource for Advanced Car Instrument Collection Repair Work Methods

In the realm of modern auto maintenance, the intricacies of instrument collection repair stand as an important aspect of ensuring the optimal performance of a lorry (tahoe instrument cluster repair). As modern technology advancements, so do the complexities of these essential parts, necessitating a detailed understanding of innovative repair work strategies. With a myriad of prospective issues that can arise within tool collections, having a reputable source that supplies in-depth assistance on troubleshooting and rectifying these obstacles ends up being paramount. By checking out the devices required, usual troubles experienced, and detailed repair service approaches, one can outfit themselves with the expertise required to navigate the detailed globe of automobile instrument cluster repair work with self-confidence and accuracy.

Importance of Advanced Instrument Cluster Fixing

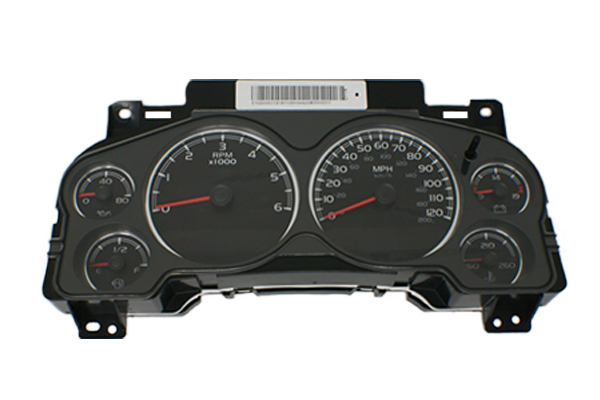

Recognizing the value of sophisticated tool collection repair is vital for maintaining the capability and accuracy of modern-day vehicle systems. The tool collection functions as the center of info for motorists, displaying crucial data such as rate, fuel degrees, engine temperature level, and alerting signs. With the improvement of modern technology, instrument clusters have actually advanced to include intricate electronic displays and digital components, making repair services extra complex and specialized.

Appropriate repair work and upkeep of the tool collection are important for ensuring the safety and security and efficiency of the vehicle. Problems with the instrument cluster can cause unreliable analyses, malfunctions in essential systems, and security threats when driving. Advanced tool cluster fixing methods entail diagnosing digital mistakes, rectifying sensors, and reprogramming software to recover optimum efficiency.

Tools and Devices Required

To effectively address the detailed fixing requirements of modern lorry tool clusters, a specialized set of devices and equipment is necessary. A few of the trick tools needed for advanced auto instrument cluster repair service include precision screwdrivers, trim elimination tools, soldering equipment, digital multimeters, and analysis scanners. Accuracy screwdrivers are essential for taking apart the cluster without creating damages. Cut elimination devices help in safely spying off panels and bezels. Soldering devices is essential for repairing busted connections or replacing elements. Digital multimeters are utilized to measure voltage, continuity, and resistance during analysis treatments. Analysis scanners are necessary for recognizing and fixing digital concerns within the tool cluster. In addition, having a top quality blowpipe, desoldering pump, and solder wire is necessary for performing complex soldering work. Correct lighting, a magnifying glass, and a clean work area are also essential for guaranteeing accuracy and accuracy during repair services. By having these specialized devices and equipment handy, service technicians can successfully diagnose and resolve complicated problems in automobile tool collections.

Usual Issues and Solutions

Numerous common issues frequently encountered in vehicle tool clusters can be successfully resolved via targeted services. One widespread issue is damaged assesses, which might arise from a malfunctioning stepper electric motor. To resolve this, changing the stepper electric Learn More motor can recover accurate scale readings. An additional typical concern is flickering or dim lights on the instrument cluster (tahoe instrument cluster repair). This can often be associated to a faulty light bulb or inadequate links. By changing the bulb or making sure safe and secure links, the lights problem can be quickly corrected. Furthermore, a malfunctioning odometer or display screen is a constant issue. This can be because of a faulty display device that needs to be replaced to bring back correct performance. Recurring power or complete failing of the instrument cluster may stem from a blown fuse or circuitry problem. Monitoring and changing the fuse, in addition to checking the circuitry for any type of problems, can assist deal with these power-related issues efficiently. By identifying these typical issues and applying the suitable remedies, vehicle tool collection capability can be brought back effectively.

Step-by-Step Repair Service Overview

A methodical method to identifying and repairing automobile instrument collection concerns is vital for accomplishing precise and reliable outcomes. To begin the fixing process, the first action is to meticulously evaluate the instrument cluster for any type of visible damages such as burnt-out bulbs, fractured displays, or loose connections.

Tips for Preventative Upkeep

After performing a detailed analysis check and completing necessary repairs on the automobile instrument cluster, executing routine preventative upkeep steps is essential to guarantee long-term performance and optimal performance of the automobile's crucial gauges and indicators. To begin, it is vital to regularly check the tool cluster for any kind of signs of wear, such as fading screens or malfunctioning lights.

Furthermore, updating the software of the tool cluster when essential can ensure compatibility with any review new functions or systems in the vehicle. It is additionally recommended to adhere to the supplier's recommended upkeep routine and guidelines for the instrument collection to keep its longevity. By integrating these preventative upkeep suggestions into your regular lorry treatment, you can aid expand the lifespan and reliability of your vehicle instrument cluster.

Verdict

To conclude, sophisticated car tool collection repair work strategies are necessary for maintaining the performance of contemporary cars. By using the correct devices and equipment, dealing with usual concerns, and adhering to a step-by-step repair guide, service technicians can efficiently deal with and detect instrument collection troubles. Implementing preventative maintenance strategies can assist extend the life-span of the tool collection and avoid future problems from emerging.

By checking out the tools needed, common problems experienced, and detailed repair work methods, one can outfit themselves with the expertise required to navigate the complex world of auto tool cluster repair service with self-confidence and precision.

A systematic method to diagnosing and fixing automobile tool cluster concerns is important for achieving accurate and effective directory results. By following this detailed overview thoroughly, automobile technicians can successfully fix and diagnose instrument collection problems with precision and confidence.

In verdict, innovative vehicle instrument cluster repair service methods are vital for maintaining the functionality of modern vehicles. By making use of the appropriate tools and devices, dealing with common problems, and adhering to a step-by-step fixing guide, technicians can successfully repair and detect tool collection troubles.

Report this page